Completed: 2018

Location: South Australia

Key Points:

- Site structural inspection leads to delivering a cost-efficient maintenance plan

- Detailed structural engineering expertise utilised

- Inspection summary/recommendation report delivered

- 2030 design life has been calculated to be achieved

The Brief

IME Consultants (IMEC) were engaged to complete conceptual design engineering of a temporary aluminium platform required to access the jacket legs/caissons of an offshore platform for inspection/maintenance.

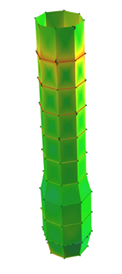

The team were required to complete site inspection of 3 x visibly corroded steel chimney stacks, advise critical areas for NDT inspection to the NDT contractor and then interpret the results by completing a structural model of the degraded stacks and recommend maintenance activities to extend the life of the stacks until 2030.

The Challenge

The existing method for accessing the jacket members involved the construction of large hung scaffolds which are manhour intensive and as well as scaffold materials taking up laydown area space, which is at a premium offshore. Due to the relatively long time taken to construct large scaffolding, precious bed space is also heavily utilised via this method.

Recommendation

By attending site with the NDT contractor, IMEC were able to drive cost efficiencies for the head client by enabling a targeted inspection campaign utilising our in-house knowledge of steel structural design. IMEC were also able to utilise our Project Engineering experience to drive activities on site and proactively deal with emergent issues arising due to access limitations not identified by the NDT contractor prior to mobilisation.

Once site inspections and NDT were completed, IMEC interpreted the data collected from site to form an as built current condition structural model of the stacks to determine where over stresses may occur in future by forecasting consistent corrosion until the required 2030 design life. At this point, IMEC were able to prescribe critical maintenance tasks and strengthening requirements to the structure to achieve the 2030 design life.

IMEC’s proactive approach on site coupled with senior structural engineering capabilities enabled a cost-efficient maintenance plan to be formulated for the head client to achieve the required life extension.