IMEC has extensive experience in Structural Integrity (SI) inspections working in accordance with local legislative requirements and standards, or in adherence with client’s requirements, we deliver outcomes that protect the interests of our clients and their assets.

Under the direction of client requirements, our approach to inspections encapsulate:

- Pre site preparedness

- Defect identification

- Risk Matrix – understanding the probability and consequence outcomes for accurate defect classification.

- Preventative maintenance and remediation

- Reporting and record keeping (photos, defect lists, remedial actions list)

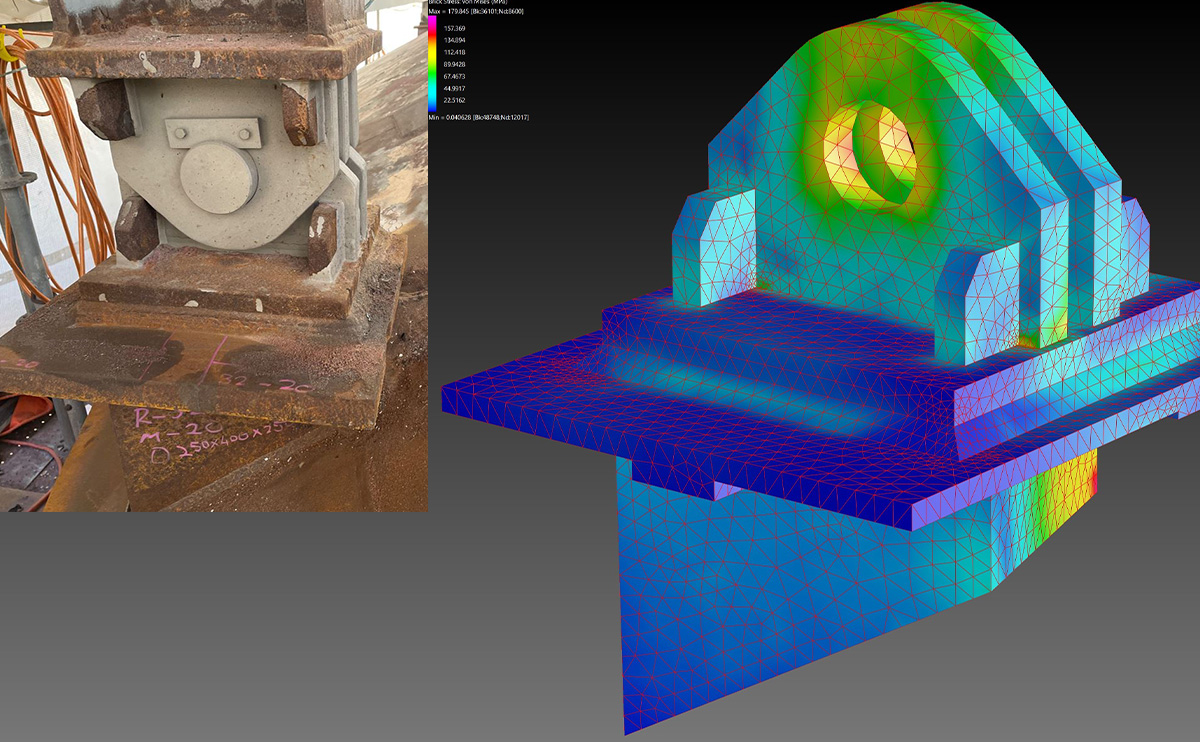

If high risk defects are identified, our in-house design team can promptly support with:

- structural condition analysis and assessment,

- design of temporary support bracing or props

- design and drafting for repair works

Project Samples

- CBH – Geraldton Grain Silo’s

- Cornish Metals– Headframe – UK

- Glencore – George Fisher – Batch Plant, power station – QLD

- Glencore – Lady Loretta – Process plant, crushing circuit, power station – QLD

- Red 5 – Darlot Gold Mine – Process Plant – WA

- Shark Bay Salt Joint Venture – Process Plant, Ship Loaded & Mine Site Infrastructure

- Gorgon – Barrow Island LNG & Wheatstone LNG Facility Including Offshore Platforms

- St Barbara – Gwalia Gold Mine – Camp – WA

- Mincor – Long Mine Kambalda – Paste Plant, Primary Ventilation stations – WA

- Hanson – Batch Plants – (WA wide)